How To Remove Tss From Wastewater

10 Tips to Lower Your BOD/TSS

- TSS/BOD levels must adhere to state environmental regulations

- High TSS levels can cause severe harm to wildlife and can make water unpalatable or even dangerous to man health

- Elevated TSS levels tin can impairment your wastewater equipment and bear upon its efficiency and operation

- Loftier BOD tin can harm or kill aquatic life

Fortunately, at that place are some effective means to keep your BOD and TSS under control. These are the best practices for reducing BOD and TSS that facility managers should know:

1. Focus on removing TSS from wastewater first.

Reducing TSS will almost always reduce BOD too. First and foremost, use mechanical screens such as roto-strainers or bar screens to go big solids out. This will as well protect your downstream Dissolved Air Flotation (DAF) equipment from damage or clogging.

ii. Get a properly sized EQ tank.

Changes in menstruum and loading rates can crusade over or underfeeding of flocculants and coagulants. A properly sized EQ tank will help balance out your menstruum and loading rates. This volition also help to properly size the polymer make-downwardly feeder, keeping your initial costs down.

3. Control the pH of the waste stream.

Effective wastewater handling chemistry has an optimum pH window where it is virtually efficient. If the pH swings to either side of this window, polymer will exist wasted or ineffective.

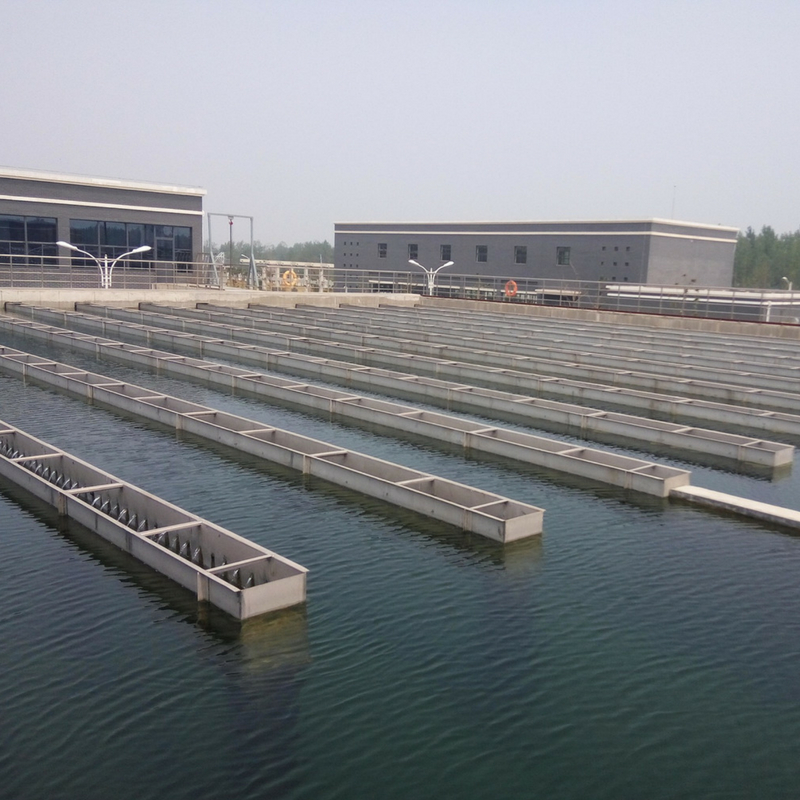

4. Install a modernistic plate pack DAF made of stainless steel or plastic.

A mod plate pack DAF will improve your TSS removal rates. It will also reduce the footprint size of the DAF and requite you lot more leeway with flow and load tolerance.

five. Use a regenerative turbine air dissolution pump.

A regenerative turbine aeration pump uses minimal electricity to dissolve air into water and produce xx-30-micron air bubbles. These are needed for efficient DAF treatment. Wait for a Nikuni brand or like pump. Nosotros recommend air flow rates in the range of 150 – 200 cfh.

6. Become a DAF that cleans itself.

Modern high-rate DAFs require takedown and cleaning about every 2 weeks. And if y'all don't clean it, you may be faced with clogging, solids separation problems, higher chemical feed rates, and higher TSS. Rather than clean it yourself, get a DAF that is self-draining and cocky-cleaning to save yourself a lot of work. Properly designed DAF systems provide cleanout ports or pumps to remove stubborn, heavy, settled solids.

7. Use performance-tested liquid chemical science whenever possible.

Using liquid chemistry allows for full automation of the process at a low price, eliminates wetting bug and fish optics (undissolved clumps of polymer particles), and opens up a wide range of treatment chemistries. It is also much easier to switch products when a drum or tote runs out than to expect or discard a palate of dry out pocketbook polymer.

8. Utilise a period proportional dosing and make-down system.

Even with a properly sized EQ tank, you should still utilise a flow proportional dosing system to compensate for flow cycling. Expect for a flow meter with a 4-xx ma output point to the chemical feed system. This volition yield more consistency, produce better overall treatment removal, and lower chemical usage.

9. Properly locate chemic injection points and exam them.

Ideally, yous should inject the coagulant starting time equally far upstream as possible. This would be where the wastewater comes out of the EQ tank, ahead of the transfer pump. Inject the polymer into a port in the flocculator tube. You'll need a sample tap placed ahead of the polymer injection port to check the coagulant dose for pin floc formation. Another sample port downstream of the polymer injection port checks the effectiveness of your chemicals prior to entry into the DAF. You tin can so make adjustments before the effluent comes out of the DAF.

10. Utilize the correct size DAF equipment.

There's only then much that chemical treatment can do. An undersized DAF or chemic feed equipment will issue in poor TSS removal rates and chemical programme failure. Companies are continually increasing production and flow rates, so y'all need to size your equipment with potential increases in listen. Many of these issues are not due to the chemical plan: they are a consequence of a malfunction in the DAF equipment's performance or maintenance.

Knowing how to control TSS and BOD is a crucial office of your wastewater treatment programme. Merely as a facility managing director, y'all're also dealing with things like cooling water systems and water treatment equipment maintenance. Download our gratuitous eBook,v Things Successful Facilities Get Right With Water Treatment, to get real industry insight into what you tin can do to relieve money and go along your systems safe.

Source: https://hohwatertechnology.com/blog/tips-reducing-bod-tss/

0 Response to "How To Remove Tss From Wastewater"

Post a Comment